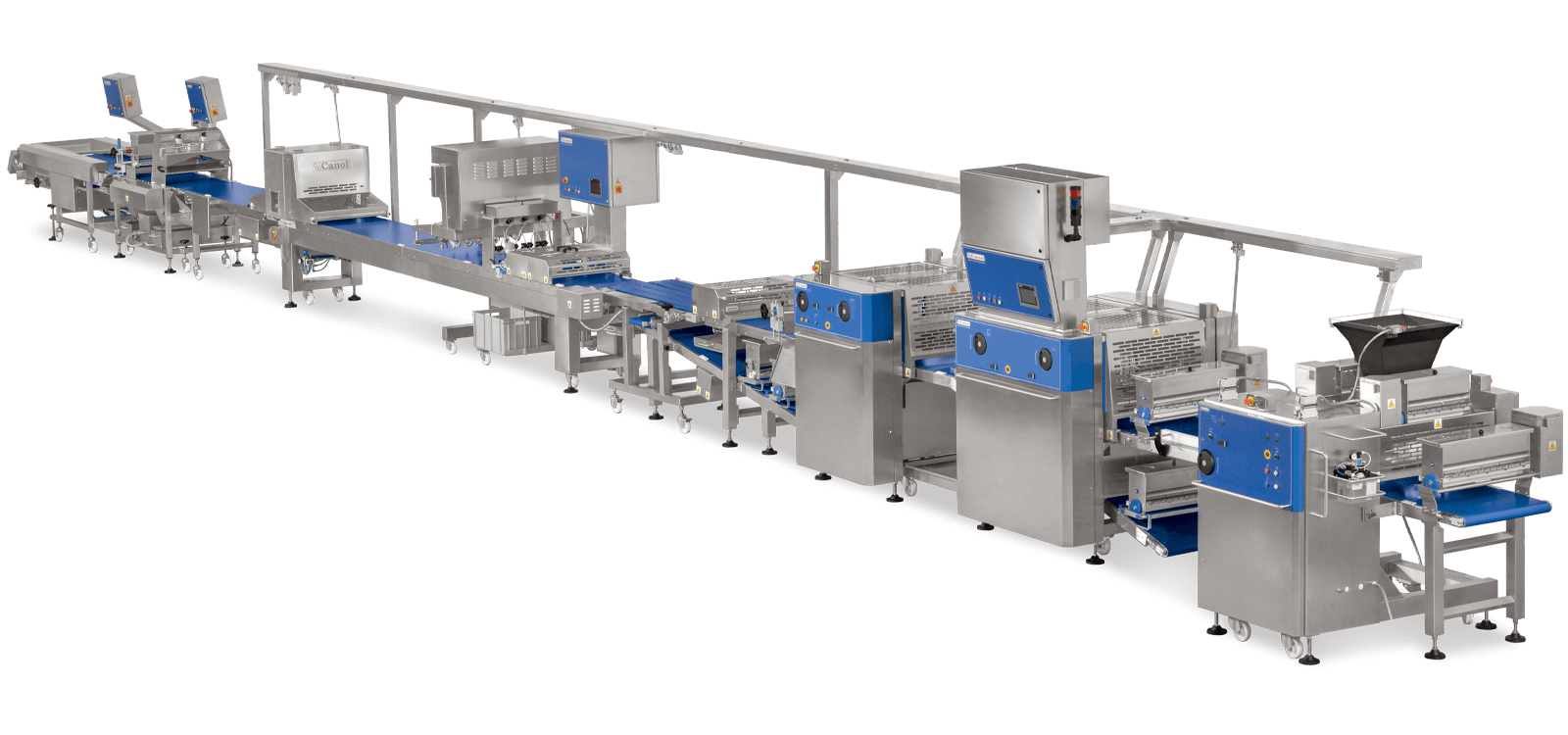

BREAD LINE

BREAD LINE

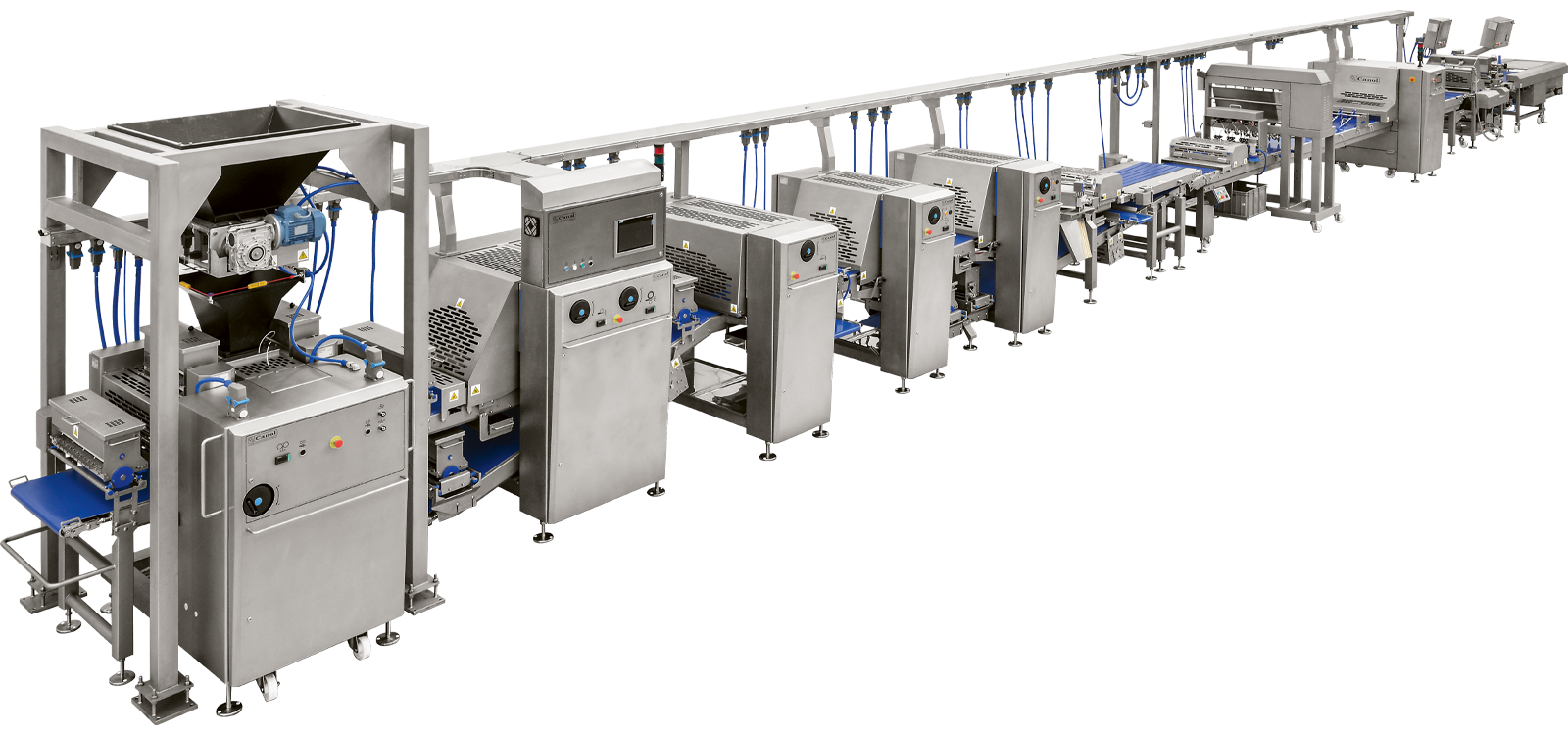

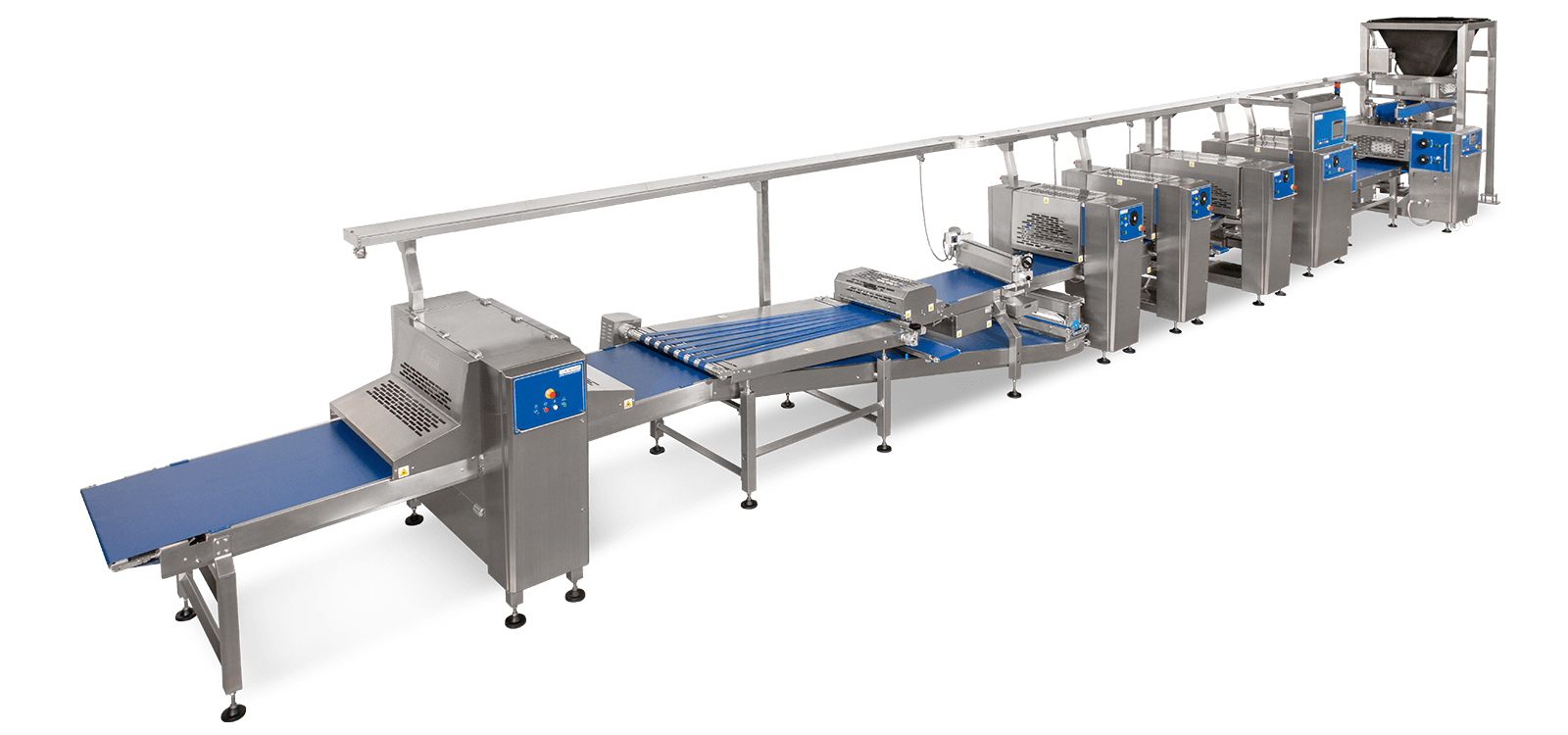

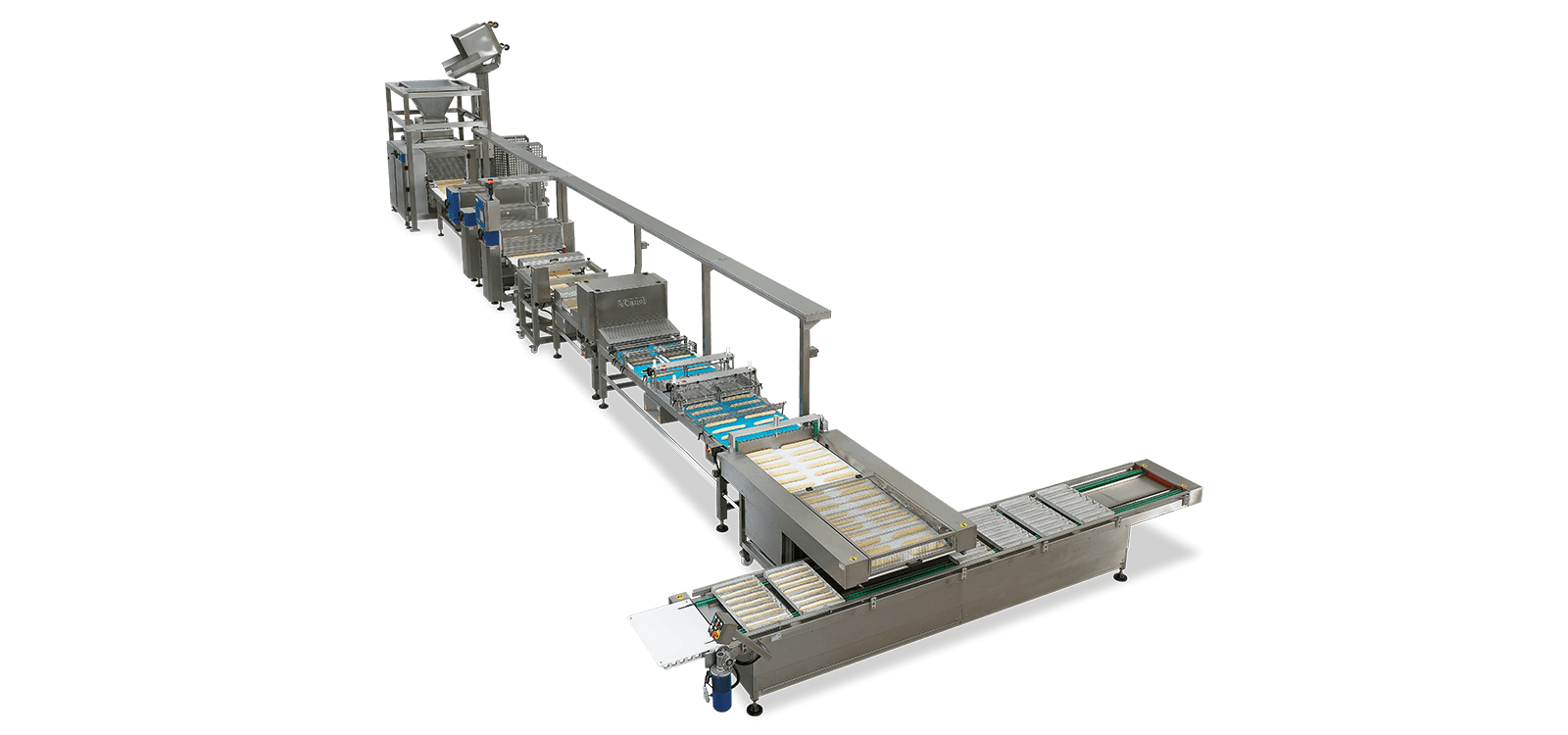

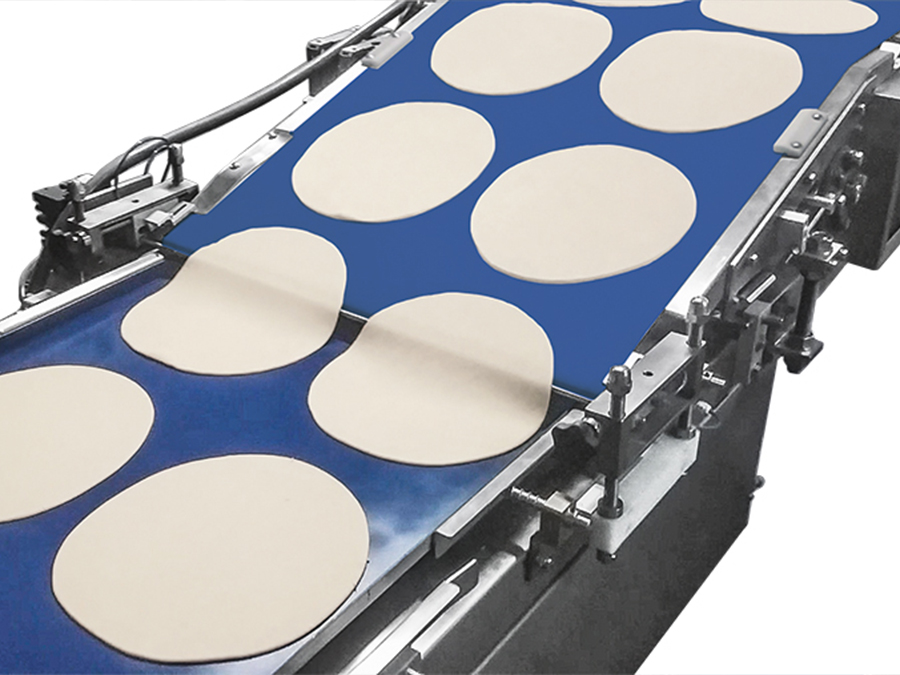

Our lines are capable of producing both laminated bread products such as ciabatta, sandwiches, and focaccia and rolled bread products such as baguettes and rustic loaves.

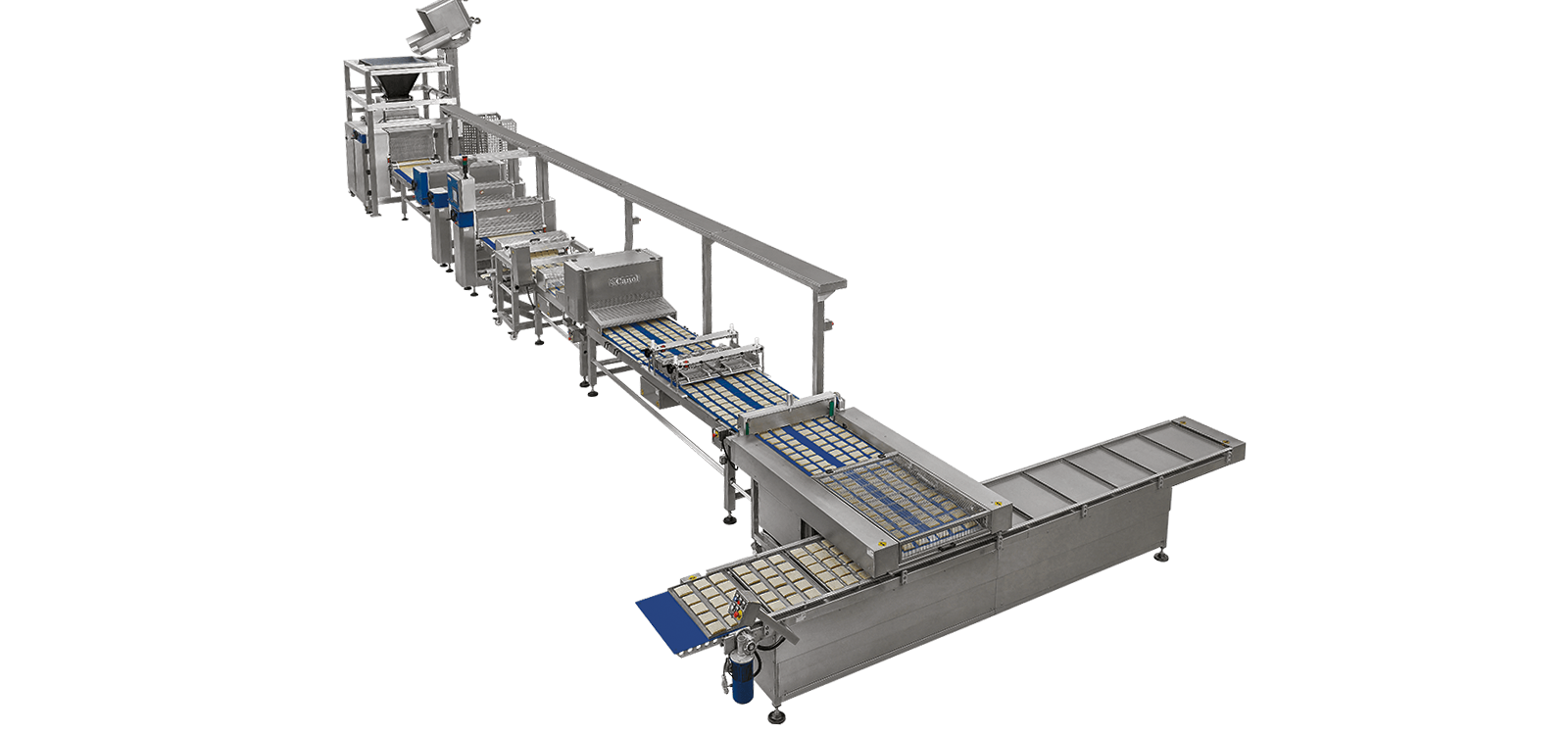

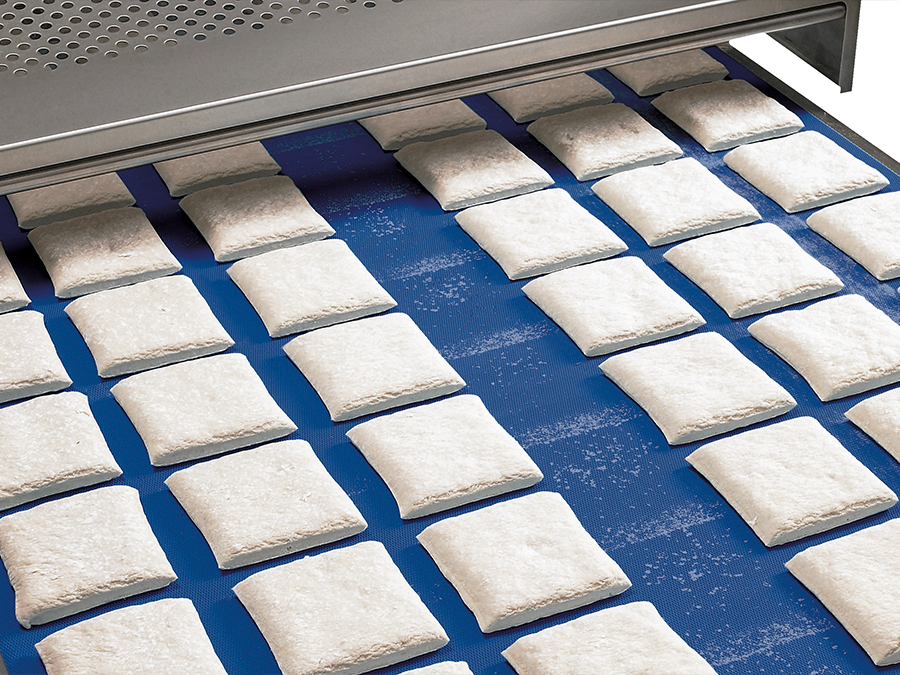

Our lines allow producing laminated bread products of different shapes and sizes from the more traditional square and rectangular to triangular and trapezoidal shapes through the extrusion and subsequent lamination of a continuous band of dough and the use of special cutting tools.

Thanks to the “Zero Stress” technology applied to our dough extruder it is possible to gently process many types of yeast doughs with high hydration, safeguarding the gluten mesh and preventing the loss of rising gases from the dough itself. Thanks to this technology the quality of the finished product, frozen or baked, is mostly superior to the traditional processes and lines.

Bread lines can integrate product wetting systems with water or liquid solutions, oiling systems and seed sprinkling stations with possible recovery and recycling of excess seeds.

Canol bread lines are characterised by their flexibility as they can be used for different product shapes and sizes and for different dough types thanks to the easy and quick handling of product changes.

Canol lines are characterised by their reliability and highly advanced technological solutions that allow for intensive use and limited maintenance thanks to the high quality of the components used in our lines and the multiple construction checks to which we subject each individual component.

Our bread lines are also designed according to hygienic design criteria that allow for an easier cleaning and avoid as far as possible the retention points of flour and dust in general, meeting the high hygienic standards required by the food industry.

Lines of different capacities and working widths are available to meet the specific requirements of each customer.

multi purpose line